Stationary brand worlds

The stationary brand worlds segment has established itself very successfully within our business for many years now. Quality, flexibility and durability are the hallmarks of our solutions – whether for flagship stores, showrooms, outlets or shop-in-shop systems. The result: a strong emotional experience, and an individual message on the basis of the highest quality production standards. And maximum sales dependability for our clients.

Shop fitting

From outlets to flagship stores, we solve the tasks and projects for each of our clients in a very individual way. And our commitment to quality and durability is just as high: from prototypes to pilot projects, from series production to roll-outs. In this way we create the magical moments crucial for retailing success, nationally and internationally, whatever the specific sector.

Interior fitting

Interior fitting as the overall term for all types of stationary brand worlds is the name we use for projects which are not directly or exclusively aimed at sales, such as showrooms, foyers, museums or cafeterias. As is the case with all stationary brand worlds, the aim here is to bring alive a space with the proper feel for surfaces, colours and shapes, and to give it an unmistakable look via materials, lighting and details.

Shop-in-Shop

Shop-in-shop solutions not only present a brand, they also highlight them within the restless surroundings of the retail environment. They transport their identity, ensure transparency and the provision of information, and thus generate a pleasant shopping atmosphere. Even under difficult conditions, such as spatial restrictions or other complicated situations.

Our process

Project development

Project development includes detailed communication on the purpose of the project as well as co-ordinating all of the realisation phases. It is one of our priorities to ensure that our customers deal with the same contact throughout the whole process from end to end.

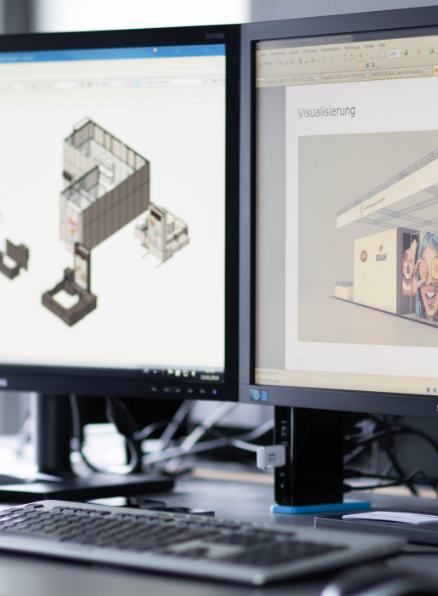

Planning

Draft planning and visualisation supplement our services depending on the type of project. For the execution planning, the technical elaboration of the project is run on CAD/CAM systems. The proper realisation of the plans and ideas then takes place in close co-operation with manufacturing and production planning.

Prototype construction

We produce prototypes in the sense of value engineering to enable us to adjust the final details in co-operation with our clients. This allows the efficient structuring of the costs and quality of the series production.

Production

Ultra-modern production technologies, and our conditions for series production, are just as much part of the production process as traditional craftsmanship. Their clever combination guarantees the high quality implementation of the plans. In addition to our own production, the use of system components and rental furniture ensures flexibility and cost optimisation.

Intermediate storage

Professional intermediate storage can naturally also be provided prior to the roll-out part of the overall process.

Logistic & assembly

The smooth order picking and packaging of all products, individual components and consumables – combined with well thought-out logistics organisation – are the basis for our structured, uncomplicated assembly.

Do you have a project?

We have the experts!